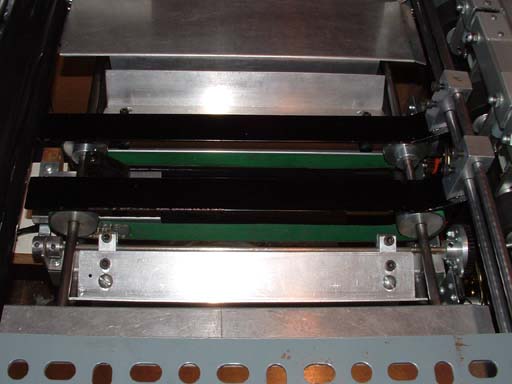

An early stage of construction before the folding rails were added. Sprung pads under the belts (one visible here) were used initially in an attempt to improve the grip of the belts, but have since been removed, because they resulted in too much friction between the paper and the rails.

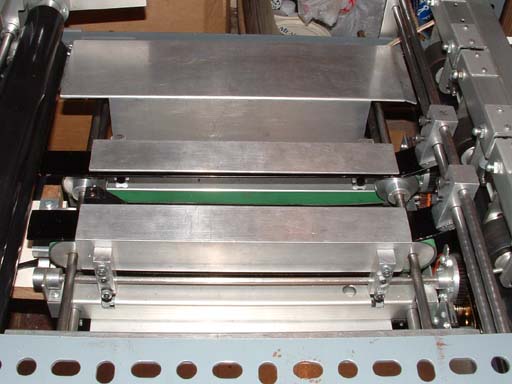

Another early view showing one flap mechanism with the flap raised. The grey metal platform was later replaced with the narrow rails shown below, to reduce friction.

Recent view, including folding rails. The rails are painted and polished to minimise friction. Side panels have been added to support the paper before folding.

Folding flaps in the raised position.

A phototransistor detects when the paper has reached the correct position for folding, and when it has passed through the creasing rollers after folding.